In the bustling world of culinary arts, where innovation meets tradition, groundbreaking technology is making waves—waterjet cutting.

This cutting-edge method, traditionally associated with industrial manufacturing, has found a new realm of application in commercial kitchens, revolutionizing how chefs process and present their culinary creations.

Imagine slicing through a watermelon, crafting intricate designs on a sheet of nori, or precisely cutting a slab of frozen beef, all without a traditional blade. Waterjet cutting, a marvel of modern engineering, makes this possible.

By employing a high-pressure stream of water, often mixed with abrasives, this technology can cut through various materials with precision and ease, leaving behind no heat-affected zones or rough edges. Its relevance to the food industry lies not just in the precision and versatility it offers but also in its ability to uphold stringent hygiene standards critical in food processing.

What is Waterjet Cutting?

Waterjet cutting is a process that utilizes a fine jet of water, expelled at high velocities, to cut through materials. This method is differentiated by its basic mechanism, which involves:

Generating a high-pressure stream of water.

Focusing this stream through a precision nozzle.

Optionally mixing the water with abrasive particles for cutting harder materials.

The beauty of waterjet cutting lies in its simplicity and the sheer versatility it brings to the table—quite literally when it comes to food.

Why Use Waterjet Cutting in Commercial Kitchens?

The application of waterjet cutting in commercial kitchens introduces a myriad of benefits, transforming mundane tasks into art and efficiency. Among its advantages are:

- Precision: Waterjet cutting allows for intricate designs and precise cuts, perfect for delicate presentations.

- Versatility: Capable of cutting a wide range of foods, from soft fruits to frozen meats.

- Hygiene: The process minimizes the risk of contamination, enhancing food safety.

Can Waterjet Cutting Improve Food Safety?

Indeed, waterjet cutting minimizes contamination risks by eliminating the need for multiple cutting tools and surfaces, reducing the chances of cross-contamination. This aspect is crucial in kitchens where food safety is paramount.

How Does Waterjet Cutting Enhance Food Presentation?

Through precision cuts, waterjet technology enables chefs to explore creative presentations, from detailed logos on confectionaries to intricate vegetable garnishes, enhancing the visual appeal and overall dining experience.

How Does Waterjet Cutting Work?

The process of waterjet cutting involves several key stages:

- Generating high-pressure water.

- Focusing the water through a precision nozzle.

- Delivering the jet to the material with controlled movement.

This sequence ensures that materials are cut accurately and efficiently, catering to the specific needs of food processing.

What Types of Foods Can Be Cut With Waterjet Technology?

Waterjet cutting is remarkably versatile, suitable for:

- Fruits and Vegetables: For delicate or intricate cuts without bruising.

- Meats: Including frozen varieties, cut cleanly without thawing.

- Frozen Foods: From ice cream to frozen desserts, cut without altering their state.

- Baked Goods: Precise shapes and designs without deforming the texture.

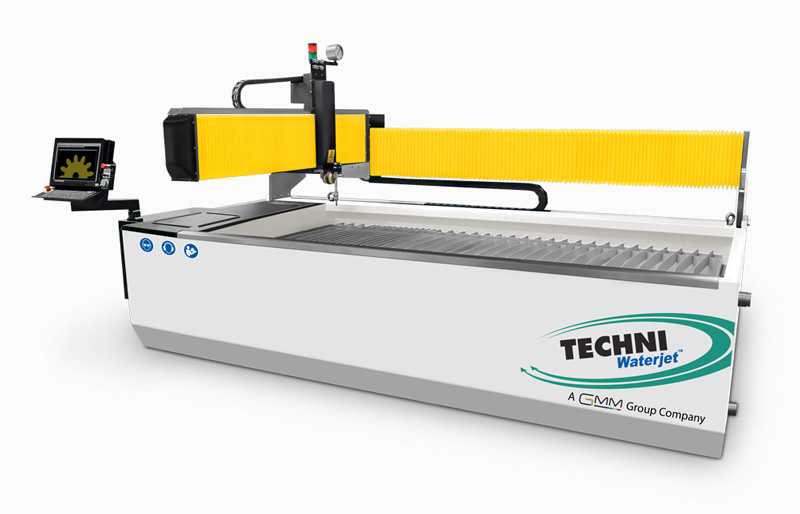

What Are the Components of a Waterjet Cutting Machine?

A waterjet cutter comprises:

- High-Pressure Pump: Generates the water pressure needed for cutting.

- Nozzle: Focuses the water stream into a fine jet.

- Abrasive Hopper: Supplies abrasive materials for cutting harder substances.

- Control System: Manages the cutter’s movements for precision and complexity.

The Advantages of Waterjet Cutting in Commercial Kitchens

Waterjet cutting offers unparalleled benefits in culinary settings, including:

- No Heat-Affected Zones: Ensuring the integrity of the food is maintained.

- Clean Cuts: Produces smooth, precise edges without any fraying or bruising.

- Ability to Cut Various Materials: From soft fruits to hard frozen meats, accommodating a wide range of culinary needs.

Setting Up a Waterjet Cutter in Your Kitchen

Integrating waterjet technology requires careful consideration of:

Space: Ensuring adequate room for the machine and its operation.

Water and Power Requirements: Necessary infrastructure for its functioning.

Maintenance: Regular upkeep to ensure longevity and performance.

Choosing the Right Waterjet Cutting Machine

Selecting a waterjet cutter involves considering:

Size and Power: To match the kitchen’s capacity and processing needs.

Features Specific to Food Processing: Ensuring they align with culinary requirements.

Installation and Maintenance

Proper installation and maintenance are crucial for optimal operation, involving:

Installation Guidelines: Ensuring the machine is set up correctly.

Ongoing Maintenance: Regular checks and servicing to maintain efficiency and safety.

Operating a Waterjet Cutter: Best Practices

Efficient and safe operation hinges on:

Training and Safety Protocols: Essential for operators to avoid accidents.

Optimizing Settings for Different Foods: Adjusting waterjet parameters for the best cutting results.

Innovative Applications of Waterjet Cutting in Food Design

Chefs and food processors are leveraging waterjet cutting to push the boundaries of food design, creating edible masterpieces that dazzle and delight.

Waterjet Cutting vs. Other Cutting Technologies

When compared to traditional knife cutting, laser, and ultrasonic technologies, waterjet cutting stands out for its versatility, efficiency, and minimal impact on food quality, offering a compelling alternative for forward-thinking kitchens.

The Future of Waterjet Cutting in the Culinary World

As technology evolves, so too will its applications in the culinary arts, promising even more innovative and efficient ways to process and present food.

Conclusion

Waterjet cutting, with its precision, versatility, and hygiene, is set to revolutionize commercial kitchens. As chefs and food processors explore its potential, the culinary world stands on the cusp of a new era, where technology and tradition converge to create unforgettable dining experiences. This guide has offered a glimpse into the transformative power of waterjet cutting, marking the beginning of an exciting journey into the future of food preparation and presentation.